Strict Inspection Process & Dynamic Manufacturing Competency

We conduct thorough inspections to uphold the highest quality standards throughout the manufacturing process. We own industry-leading injection molding machines for vertical and horizontal insert molding.

Our Inspection Process

- First Article Inspection: Our detailed first article inspections ensure that initial production samples meet all specified requirements and criteria.

- Receiving Inspection: We meticulously inspect incoming materials and components to verify their quality and conformity to specifications.

- In-Process Inspection: Continuous in-process inspections guarantee that quality standards are maintained at every stage of production.

Production Part Approval Process (PPAP)

ACLARYN PLASTICS INC is proficient in executing PPAPs tailored to our customers' requirements, ensuring compliance and satisfaction. Our PPAP process guarantees that all production parts meet stringent quality standards before full-scale production begins.

Statistical Process Control (SPC)

- Identifying Process Variations: Utilizing SPC software, we monitor and analyze process variations, resulting in fewer defects and improved on-time delivery.

- Transparent Reporting: Upon request, we provide SPC data electronically to our customers, fostering transparency and collaboration in quality management.

Preventing Failures With FMEA

At ACLARYN PLASTICS INC, we prioritize preemptive measures to mitigate failures. Through Failure Mode Effects Analysis (FMEA), we proactively identify root causes of potential failures, allowing us to eliminate occurrences and minimize the impact of defects on our products.

Adherence to Environmental Directives

To mitigate the harmful effects of substances in everyday products, global environmental directives are being implemented. ACLARYN PLASTICS INC is committed to complying with these directives to minimize our impact on the planet. We prioritize the identification, maintenance, and utilization of materials that comply with current regulations.

One prominent directive is the RoHS (Restriction of Hazardous Substances), which sets limits on hazardous substances in electronic products to levels below 100-1000 ppm. Effective July 1, 2006, RoHS and equivalent directives prohibit the use of substances such as:

- Lead

- Mercury

- Polybrominated Biphenyls (PBB)

- Hexavalent Chromium

- Cadmium

- Polybrominated Diphenylethers (PBDE)

Although these directives may not currently affect all our customers, we diligently research and identify all our products to ensure they are fully RoHS compliant, thus safeguarding our customers' interests.

Our Plants

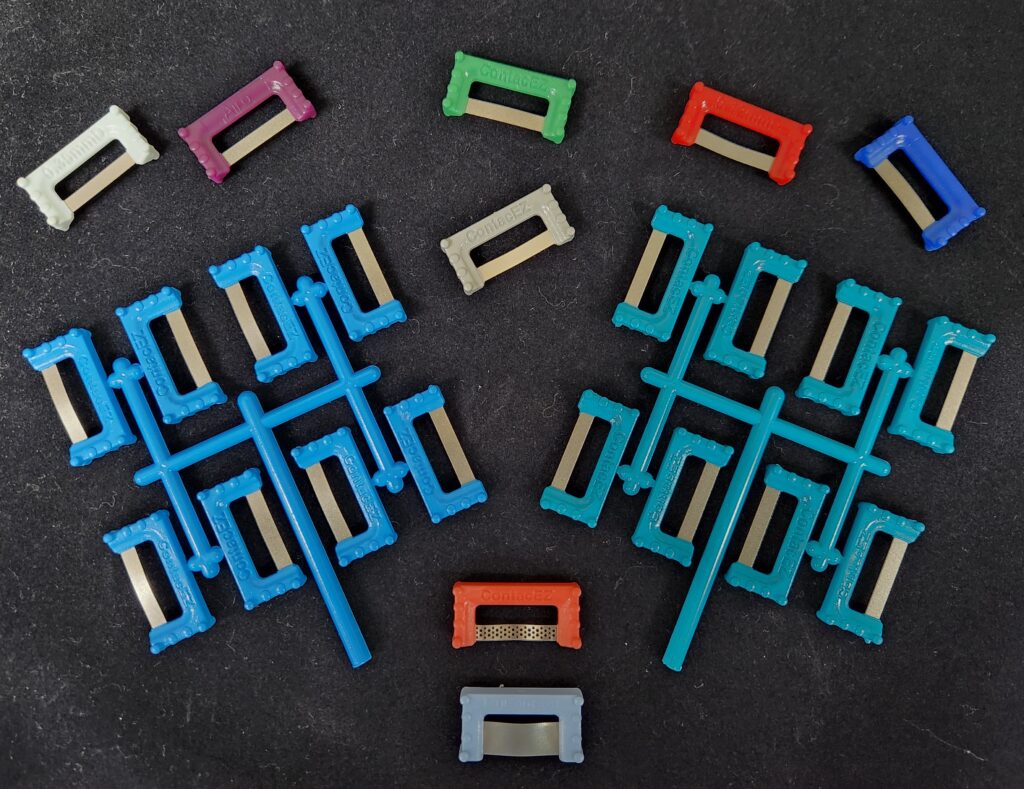

At ACLARYN PLASTICS INC, our capabilities extend beyond plastic over molding to include the design of castings, metal contacts, wire cables, and more. Collaborating with a diverse network of vendors in various manufacturing fields enables us to offer competitive pricing for tooling and components, ensuring cost-effective solutions for our clients' projects. This facilitates the transformation of ideas into tangible products.

High-Capacity Machines

- Boy 22VH: Vertical Injection Molding Machines

- Boy 22H: Horizontal Molding Machines

- Van Dorn HT 85 Ton - 170 Ton: Horizontal Molding Machines

- Toshiba Electric 200 Ton: Horizontal Molding Machines

- Dri-Air: Material Dryers

- Advantage: Mold Temperature Control Units

Whether you have a product concept to develop or need a quote, we're here to assist you every step of the way. Click the link below to request a quote for your existing products.